Industry 4.0 is presented as the new revolution in the industrial and business sector and represents a new challenge for research groups with lines of work focused on digital transformation, in search of new technological solutions that ease management and increase business competitiveness.

Industry 4.0 includes cyber-physical systems, smart products, the Internet of Things and Services, hyperconnectivity, big data, cybersecurity, cloud computing, additive manufacturing (3D printing) or robotics. Research in technologies that give rise to what is known as intelligent industry.

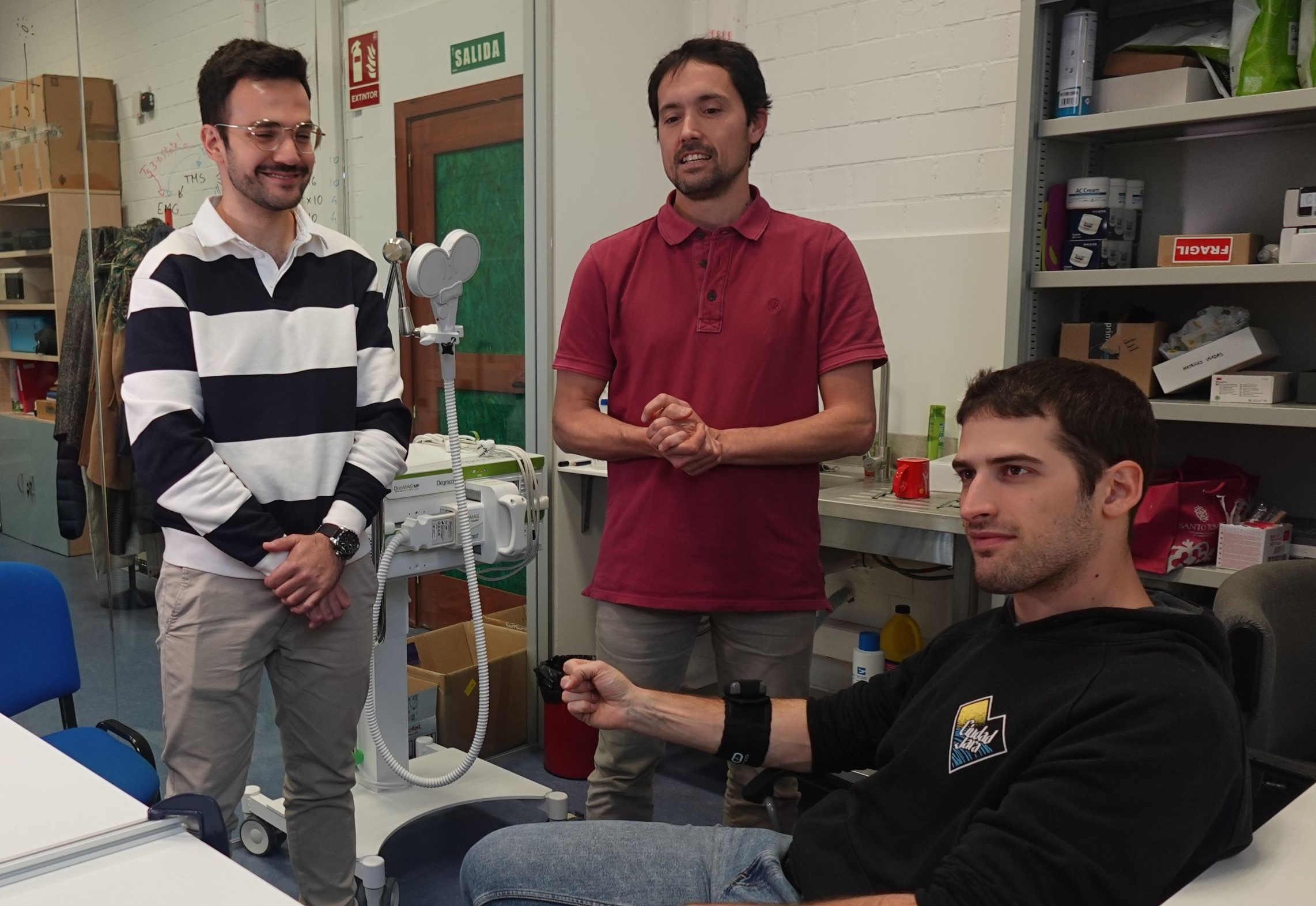

More than 30 researchers from the I3A lead lines of work in the field of Industry 4.0, with 11 projects underway around six scientific areas.

The Industry 4.0 laboratory at the I3A performs research at all levels of industrial readiness, from basic research to applied developments. It covers the different areas for cutting-edge technologies and works on:

- Certified simulation for decision making

- Internet of Things/Internet of Robotic Things

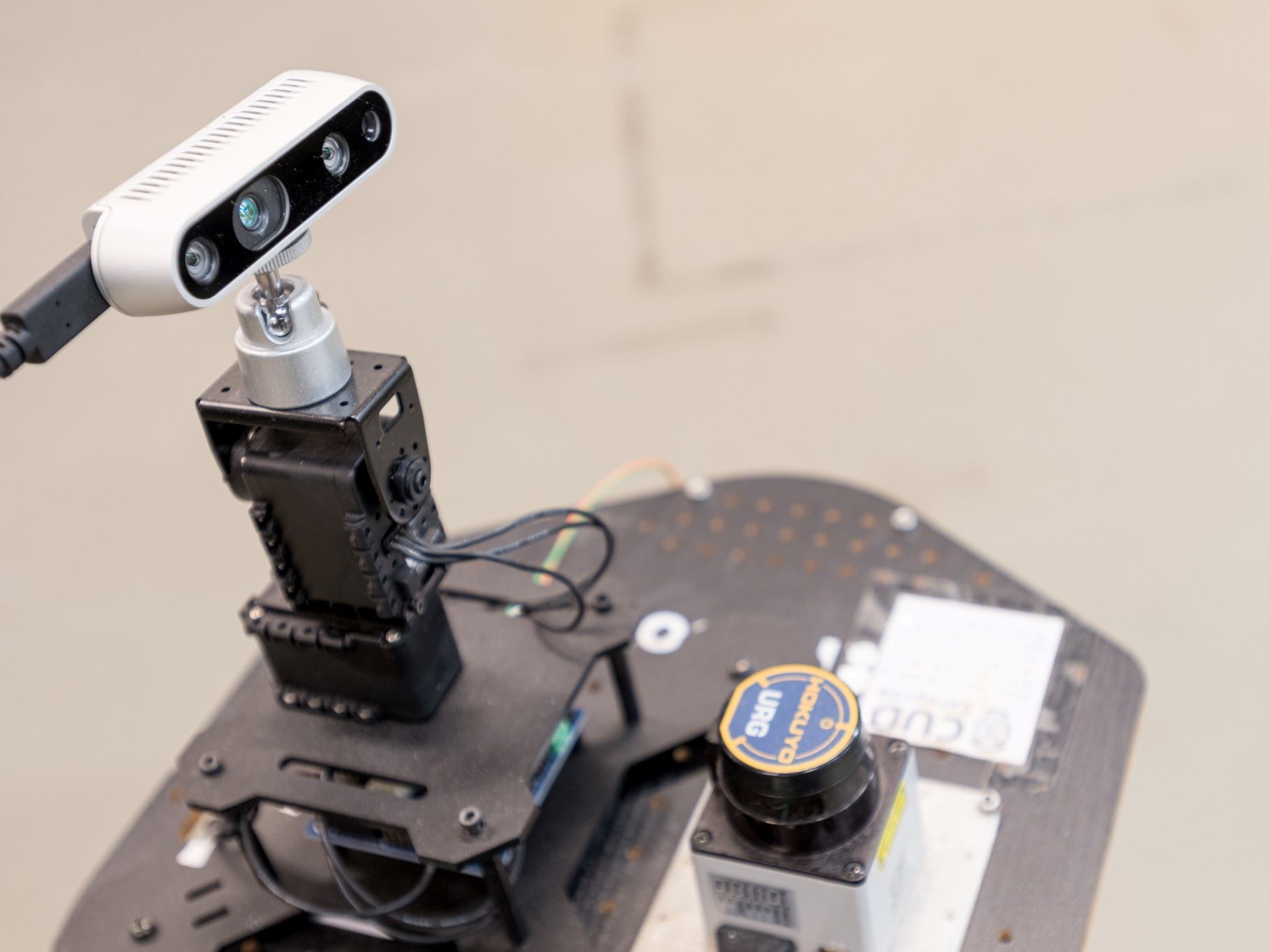

- Robotics

- Zero-defect industry

- Computer vision

- Virtual and Augmented Reality

What the Industry 4.0 lab does?

It supports and connects the growing Industry 4.0 and IoT research community, builds research capacity in Industry 4.0 to tackle complex issues, drives new research challenges through collaborative research projects, promotes and provides opportunities for knowledge transfer, identifies and provides training courses for students, academics, industry and the third sector and acts as a gateway for external organisations. Lab. Industry 4.0

Projects

AUTODUMP. Automation of debris in tunnels using robotic dumpers. +Info

Digital twin of banknote reading machines. +Info

Hardware with artificial intelligence for the detection of banknote anomalies. +Info

Digital twin in agricultural exploitation. Create an information infrastructure to support a geospatial information system for managing the sustainable use of pesticides on a farm, among other applications. +Info

Insilico. Engineering based on simulations, through computational models and numerical methods, for real-time decision making in the industry. +Info

Commandia. The search for robotic solutions to automate industrial handling and assembly tasks that they are still done manually today. +info

FROSCAT. Multi-robot systems for covering and transporting objects that are too large and heavy, difficult to grasp, too fragile or too soft to be handled by a single robot. +info

DIVCORE. It proposes a multi-robot scenario with various ground and air vehicles that perform tasks of perception, consensus and coordinated movement with vision sensors to autonomously explore and monitor an area of interest. +info

Digiman 4.0. Digital manufacturing technologies for defect-free Industry 4.0 production. +info

Credible. In the context of data-intensive science and technology, industry needs credible simulation procedures embedded in decision-making protocols. +Info

In-Fast. Procedures to increase cybersecurity and protection of critical transport infrastructure. +Info

Industry 4.0 is one of the eight Cutting-Edge Laboratories, a project launched by the I3A. They integrate the research lines of the I3A in which the groups of the institute stand out. A way of structuring all the innovative activity that is generated from this Institute, which has more than 400 researchers and 600 active projects.

Podcast: https://go.ivoox.com/rf/82836903